Products

SPACE FLIGHT HERITAGE

PYROVO Pyrolytic Graphite Film (Pyrovo™ PGF) Thermal Straps

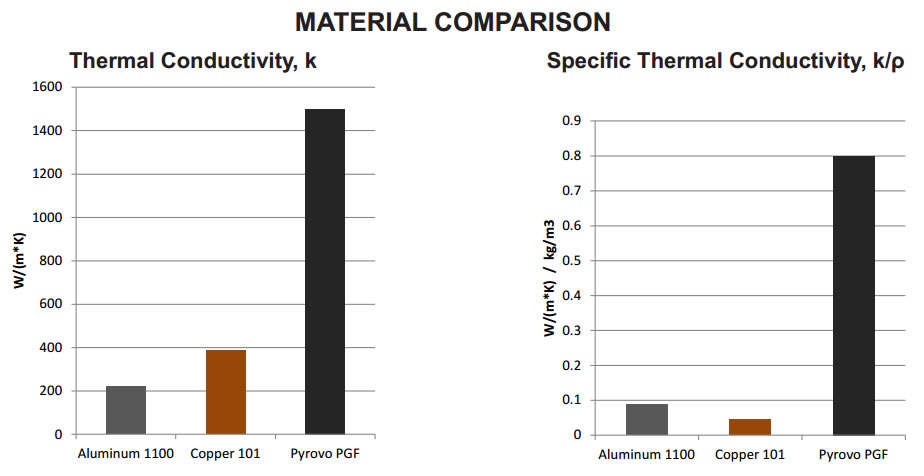

Our patent-pending Pyrovo™ PGF thermal straps are by far the most conductive, lightest, thinnest, and most flexible thermal straps available. Pyrovo™ PGF thermal straps now have flight heritage! Test results show that Pyrovo™ thermal straps have over 7x the thermal conductivity of equal size aluminum thermal straps (4x copper). This means that the same conductance can be achieved with a fraction of the bulk, mass, and stiffness. This is especially important in cooling optics and delicate electronics. Furthermore, the thermal conductivity is significantly higher at cryogenic temperatures.

For flight systems, the specific thermal conductivity (k/rho) is the figure of merit. In this regard, the advantages of Pyrovo™ PGF over aluminum and copper are even more striking: 10x better than aluminum and 20x better than copper.

Thermotive's Pyrovo™ PGF technology has several patent-pending features that address legacy contamination concerns with graphite near optics. In fact, these are probably the cleanest thermal straps ever -- contact us and we’ll show you why.

Aluminum and Copper Foil Thermal Straps

Thermotive is committed to providing the finest foil-type aluminum and copper thermal straps quickly and at low cost. We offer custom thermal straps made to your specifications as well as standardized models (Lab and Standard Series) made with Thermotive's off-the-shelf components, simplifying the procurement process, bringing down prices, and significantly shortening lead times.

Thermotive's LAB and STA-Series thermal straps can also be fabricated using copper rope or braid. For more information scroll down.

For a flexibility demonstration, watch our one-minute video.

| Lab Series | Standard Series | Custom Straps |

|---|---|---|

|

|

|

|

|

|

Series |

|||||||||

Model # |

LAB-725 |

LAB-1225 |

LAB-1100 |

STA-500 |

STA-725 |

STA-1000 |

STA-1225 |

||

Foil width |

0.725 in |

1.225 in |

1.100 in |

0.500 in |

0.725 in |

1.000 in |

1.225 in |

||

Foil alloy |

AL-1100 or CU-101 / 110 |

AL-1100 or CU-101 / 110 |

|||||||

Terminal alloy |

AL-6063 |

AL-6063 |

CU-110 |

AL-6061 / 1100 or CU-101 / 110 |

|||||

Strap thickness |

200 foils |

425 foils |

205 foils |

Made to specification |

|||||

Length of |

x (number of milimeters) |

||||||||

Est. conductance AL foils at RT |

17/x W/K |

61/x W/K |

26/x W/K |

||||||

Est. conductance CU foils at RT |

31/x W/K |

111/x W/K |

48/x W/K |

||||||

Est. conductance CU rope at RT |

25/x W/K |

89/x W/K |

38/x W/K |

||||||

Shape |

|||||||||

Terminals |

LAB-725 Block terminal (BT) |

Block terminal (BT) |

|||||||

Hole placement |

Made to specification |

Made to specification |

|||||||

* The heat path length is measured in milimeters -- mid-terminal to mid-terminal. If the heat path measures 100 mm, then x=100.

Copper Rope Thermal Straps (lower performance, most economical)

Thermotive's LAB and STA-Series thermal straps can also be fabricated using copper rope or braid. This results in a bulkier, heavier, and significantly stiffer strap in the primary bending axis when compared with a foil-type strap with the same conductance. Overall rope-type straps are stiffer, but more uniform in their ridgidity about the three bending axes. Rope-type straps are simpler to fabricate, so they offer the most economical option when stiffness, mass, and volume are less critical.

Thermoelectric thermal straps (TEC straps)

These are thermal straps that have been integrated with a carefully selected thermoelectric cooler (TEC). TEC straps provide precise temperature control by energizing the TEC and conveying thermal energy through the flexible foils, which heats or cools an interface. This can be particularly important in thermal control of temperature-sensitive scientific instruments in vacuum applications.

Standard Pyrovo™Thermal Straps

Pyrovo PGF thermal strap Part # 111 80484850 is a standard product. This folding thermal strap is used on an advanced avionics cooling application. Mass < 9 gm. Conductance of 1.5 W/K at RT.

Contact us for technical and pricing information. Discounted pricing is available for students.

Aluminum Thermal Strap Flexibility Demonstration

Aluminum vs Copper

Which is better for thermal control applications?

As with many things, the answer depends on the application. The thermal conductivity varies significantly as a function of temperature below 100K and at these temperatures it's also very sensitive to purity. The following comparison assumes operation near room temperature.

Where mass is critical, aluminum is best. By using an aluminum thermal strap you get 58% of the thermal conductivity of copper with only 30% of the mass. For mass minimizing designs the thermal conductivity-to-mass ratio is the figure of merit.

A 1kg aluminum thermal strap will have almost twice the conductance of a 1kg copper thermal strap.

The aluminum thermal strap will be 69% larger by volume, but since Aluminum has almost twice the thermal conductivity-to-mass ratio of copper, it is often the best option for flight.

The Airbus A380 takes advantage of aluminum’s higher electrical conductivity-to-mass ratio by using aluminum wiring instead of heavier but more traditional copper. JPL–NASA/CalTech’s Orbiting Carbon Observatory (OCO 2), HyTES (cryogenic airborne spectrometer), PRISM (airborne spectrometer) all use aluminum thermal straps for their thermal control hardware.

Even though copper is also 70% stiffer than aluminum, in some cases it can be an attractive choice when volume is more critical than mass. An example might be a retrofit scenario where thermal straps must be added to an existing design through a very narrow space. Here, the thermal conductivity and resulting thermal strap dimensions might be paramount.

Comparison of Aluminum and Copper as Conductors